Pneumatic

Gas

Hydraulic

Electric

Pneumatic Tools

Paving Breakers & Jackhammers

Atlas Copco pneumatic paving breakers deliver powerful concrete breaking performance for highway reconstruction, demolition, and heavy civil construction applications.

Rock Drills

Atlas Copco pneumatic rock drills provide precision drilling capability for mining, quarrying, and tunnel development operations.

Rivet Busters

Atlas Copco pneumatic rivet busters provide precision removal of rivets, bolts, and fasteners for bridge deconstruction and structural steel disassembly.

Pick Hammers & Spike Drivers

Atlas Copco pneumatic pick hammers and spike drivers for railroad track maintenance, tie removal, and ballast work on railway construction projects.

Backfill Tampers

Atlas Copco pneumatic backfill tampers for soil compaction around utility trenches, foundation excavations, and pipe installations.

Diaphram Pumps

Atlas Copco pneumatic diaphragm pumps for transferring liquids, slurries, and abrasive materials on construction and mining sites.

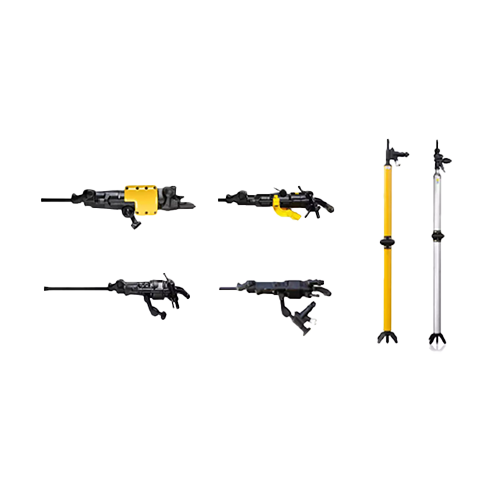

Jackleg & Stoper Drills

Atlas Copco pneumatic jackleg and stoper drills for horizontal and vertical drilling in underground mining and tunnel development.

Dust Collection Systems

Atlas Copco dust collection systems for controlling silica dust and maintaining air quality during drilling and concrete cutting operations.

Gas Tools

Paving Breakers & Jackhammers

Atlas Copco gas-powered paving breakers for concrete breaking and asphalt removal on remote jobsites without compressed air access.

Rock Drills

Atlas Copco gas-powered rock drills for drilling blast holes and anchor installations on remote quarries and construction sites.

Rail Tampers

Atlas Copco gas-powered rail tampers for ballast compaction and track stabilization on railroad maintenance projects.

Hydraulic Tools

Post Drivers

Atlas Copco hydraulic post drivers for driving fence posts, sign foundations, and guardrail supports on highway and fencing projects.

Power Packs

Atlas Copco hydraulic power packs for operating hydraulic breakers, post drivers, and concrete splitters on construction sites.

Paving Breakers & Jackhammers

Pick Hammers & Spike Drivers

Atlas Copco hydraulic pick hammers and spike drivers for railroad track maintenance with reduced operator fatigue and noise.

Post Pullers

Atlas Copco hydraulic post pullers for extracting fence posts, sign foundations, and temporary supports without excavation.

Electric Tools

Drainage Pumps

Atlas Copco electric drainage pumps for dewatering foundation excavations, underground construction, and mine sumps.

Electric Lighting

Atlas Copco electric lighting towers for illuminating construction sites, mining operations, and 24-hour project work.