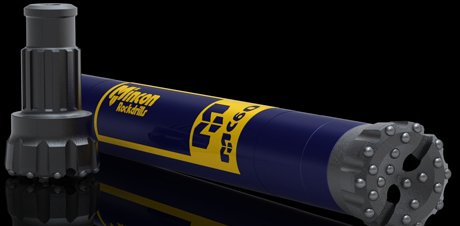

DOWN-THE-HOLE HAMMERS

12" Series Hammers

The MP-series is our comprehensive range of next generation of DH hammers, supporting dril bit sizes between 3.4" (85mm) and 60" (1524mm).

The MP-series offers unparalleled versatility and compatibility, with supports for industry-standard shanks. Additionaly, MP-series hammers are available in variants that support drill bits without a foot valve (also known as tubeless drill bits). All models in the next-generation MP-series of DTH hammers are manufactured at state-of-the art facilities in Ireland and Finland, ensuring consistenly high-quality parts and material properties, for supreme reliability, longevity and efficiency.

Applications include geothermal, shallow oil and gas, blast hole, water well, environmental, exploation and construction.

*** FREE ground shipping to non-dealers within the Continental United States

Design Highlights:

- Patented features maximize energy output and reduce service requirements

- Unique manufacturing processes extend internal components life allowing for multiple rebuilds in abrasive conditions

- Valveless operation to maximize energy output, provide efficient air utilization and reduce service requirements

- Extra air-flow system allows for better hole cleaning in troublesome holes

- Reversible hardened wear sleeve for optimum wear resistance even in the most abrasive conditions

- Multi-start threads on back head and chuck ensure easy coupling/uncoupling of hammer

- Unique internal mount system eliminates the need for wear shims and special assembly tools

- All critical internal components are heat treated under strict control to maximize tool longevity

- An overall cost-effective and user-friendly tool for use in the most demanding conditions

Mincon Hammers

$150 Flat Rate LTL/Truck Shipping to Commercial destinations*

$250 flat rate for Residential destinations in Continental US. Rates will be quoted for Alaska, Hawaii and all international destinations.

| Model | Part No. | Price |

|---|---|---|

| Mincon MP120-SD12 Hammer | MD1201AS07 | QUOTE  |

*** FREE shipping within continental United States for non-dealers

| Consumables | ||

|---|---|---|

| Bit Shank Type | Sandvik SD12/10015 | |

| Specifications | ||

|---|---|---|

| Shank Support | SD12 | |

| Foot Valve | Yes | |

| Standard Back Head Thread/Type | in | 65/8 API |

| Hammer OD | in | 10.8 |

| Hammer Length (shoulder to shoulder) | in | 56.4 |

| Minimum Bit Size | in | 12.1 |

| Maximum Bit Size | in | 15 |

| Hammer Weight | lbs | 1023 |

| Piston Weight | lbs | 288.4 |

| Model | Part No. | Price |

|---|---|---|

| Mincon MP120-N125 Hammer | MD1201AS05 | QUOTE  |

*** FREE shipping within continental United States for non-dealers

| Consumables | ||

|---|---|---|

| Bit Shank Type | N125 | |

| Specifications | ||

|---|---|---|

| Shank Support | N120 | |

| Foot Valve | Yes | |

| Standard Back Head Thread/Type | in | 65/8 API |

| Hammer OD | in | 10.8 |

| Hammer Length (shoulder to shoulder) | in | 57.2 |

| Minimum Bit Size | in | 12.1 |

| Maximum Bit Size | in | 15 |

| Hammer Weight | lbs | 1003 |

| Piston Weight | lbs | 303 |

| Model | Part No. | Price |

|---|---|---|

| Mincon MP120 QL Hammer | MD1201AS04 | QUOTE  |

*** FREE shipping within continental United States for non-dealers

| Consumables | ||

|---|---|---|

| Bit Shank Type | QL120 | |

| Specifications | ||

|---|---|---|

| Shank Support | QL120 | |

| Foot Valve | Yes | |

| Standard Back Head Thread/Type | in | 65/8 API |

| Hammer OD | in | 10.8 |

| Hammer Length (shoulder to shoulder) | in | 57.3 |

| Minimum Bit Size | in | 12.1 |

| Maximum Bit Size | in | 15 |

| Hammer Weight | lbs | 1007.6 |

| Piston Weight | lbs | 305.4 |