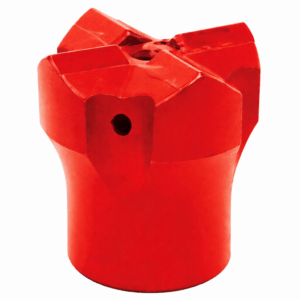

Rock Drill Bits

Showing all 13 resultsSorted by popularity

- $77.44 – QUOTESelect options This product has multiple variants. The options may be chosen on the product page

- $13.40 – QUOTESelect options This product has multiple variants. The options may be chosen on the product page

- $125.90 – QUOTESelect options This product has multiple variants. The options may be chosen on the product page

- $8.90 – $40.00Select options This product has multiple variants. The options may be chosen on the product page

- $26.20 – $92.20Select options This product has multiple variants. The options may be chosen on the product page

- $46.75 – QUOTESelect options This product has multiple variants. The options may be chosen on the product page

- $44.10 – $64.20Select options This product has multiple variants. The options may be chosen on the product page

- $157.00 – $224.00Select options This product has multiple variants. The options may be chosen on the product page

- $157.00 – QUOTESelect options This product has multiple variants. The options may be chosen on the product page

- $180.00 – QUOTESelect options This product has multiple variants. The options may be chosen on the product page

- $1.00 – $95.00Select options This product has multiple variants. The options may be chosen on the product page

- $435.16 – $2,248.06Select options This product has multiple variants. The options may be chosen on the product page

Showing all 13 resultsSorted by popularity