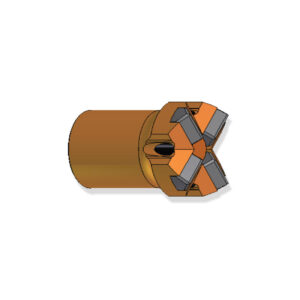

A Tapered Button Bit is a rotary drill bit that is designed with a tapered body (the diameter gradually decreases along its length) and button-shaped inserts on the face of the bit. These inserts are typically made from tungsten carbide, which provides exceptional hardness and wear resistance. The taper design allows the bit to fit into corresponding tapered drill rods, facilitating efficient drilling and reducing the risk of jamming.

- Design:The tapered shape of the bit allows for effective transmission of force during drilling. This shape ensures better stability and efficient removal of debris from the hole being drilled. The tapered design also helps with a smooth entry and easier removal of the bit from the hole. The buttons on the bit are typically made from tungsten carbide or other wear-resistant materials. These button-shaped inserts are placed in strategic locations on the bit face to provide optimal cutting action and to reduce friction, allowing for faster and more efficient drilling.

- Applications:

- Mining: Tapered button bits are extensively used for drilling in hard rock formations in underground mining operations. They are used to create blast holes for controlled explosions that break rock, allowing for extraction of ore. Tapered button bits are used to drill holes for rock bolts, which help to stabilize mine tunnels and prevent rock falls.

- Tunneling:In tunnel construction, these bits are used to drill through hard rock to create tunnels for transportation, utilities, or ventilation systems. The bits allow for precise, stable boreholes that are essential for tunnel integrity.

- Construction: Tapered button bits are used in foundation drilling for large construction projects. They help create stable boreholes for piles and anchors, which are vital for supporting structures. In road construction, these bits are used to drill holes for anchors or to break through hard layers of rock during excavation.

- Geotechnical Drilling: In geotechnical exploration, tapered button bits are used to drill holes and extract rock or soil samples for analysis. This helps engineers and geologists understand the material composition and stability of the ground before construction or mining activities begin.

- Water Well Drilling:Tapered button bits are used in water well drilling, particularly when drilling through hard rock to access water sources. These bits allow for fast, efficient drilling while preventing damage to the well casing.

- Oil and Gas Exploration: Tapered button bits are used in oil and gas exploration for drilling through various geological formations to locate and extract hydrocarbons.

- Materials:The body of the tapered button bit is typically made from high-grade alloy steel. This steel is designed to handle the significant impact and rotational forces exerted during drilling. It is often heat-treated for additional strength, durability, and resistance to fatigue. The tungsten carbide buttons are strategically placed at the most critical points of contact on the bit to ensure optimal cutting efficiency and a longer lifespan.

- Configurations: None