MADE IN THE USA

A pressure-feed line oiler is a lubrication device that injects a controlled amount of oil into a pressurized fluid line (air or other gas or even liquid) to ensure adequate lubrication of downstream components (bearings, pneumatic tools, valves, manifolds). The aluminum qualifier refers to the body or housing being made of aluminum (or aluminum alloy) which offers lightweight corrosion resistance and good mechanical strength.

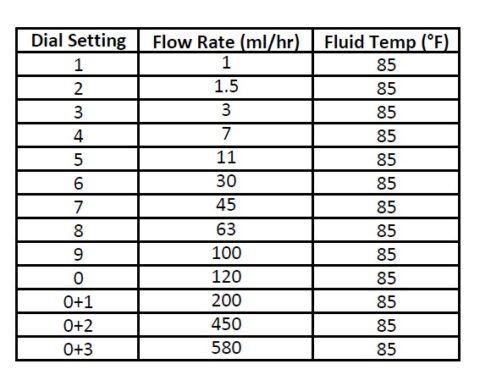

In operation: the device is installed in-line; the pressurized medium flows through or past the oiler; the oiler meters oil from its reservoir into the flow, typically via a metering valve or adjustable feed screw. The term pressure-feed indicates the oil is fed by virtue of the pressure differential in the supply line rather than purely gravity drip. For example, pneumatic in-line lubricators for air tools use this principle.

Design:

- Body/housing: Cast Aluminum

- Oil reservoir with a sight glass to monitor oil level or flow.

- Metering valve or adjustment screw to regulate oil flow into the line.

- Threaded NPT inlet/outlet ports in 1/2″, 3/4″, and 1″.